If you’re choosing between WallPro panels and traditional CHB (concrete hollow blocks), don’t start with “Which is cheaper per sqm?” Start with this better question:

Which system reduces labor hours, shortens the schedule, and cuts site waste—without sacrificing strength and finish quality?

Because in real residential builds, the biggest budget leaks come from three things:

Slow progress (extended overhead + longer labor exposure)

Labor-heavy processes (more workers, more days, more coordination risk)

Waste + rework (materials thrown away, work repeated, delays multiplied)

Here’s what actually changes when you switch from CHB to a panelized wall system like WallPro.

Quick answer (snippet-friendly)

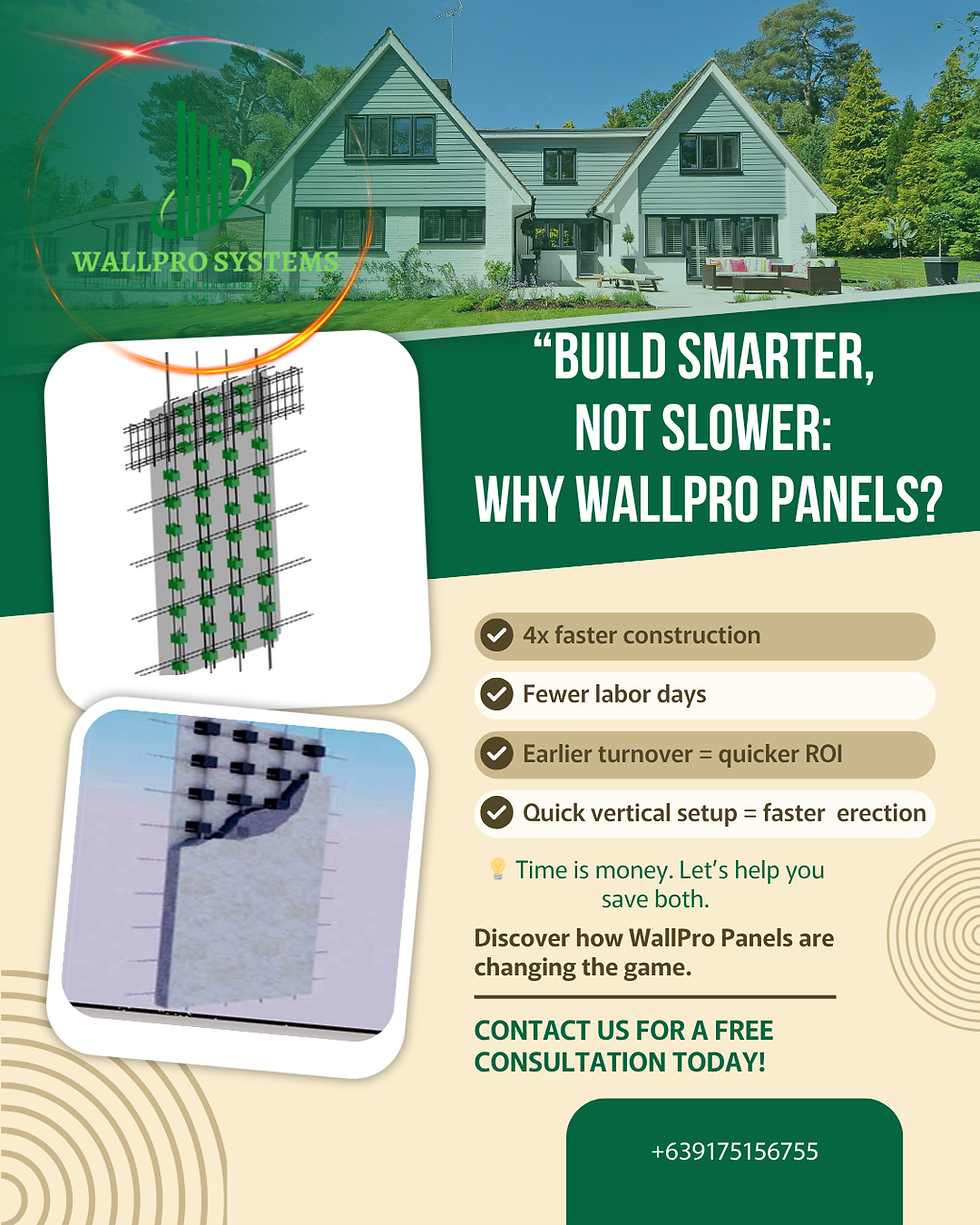

WallPro-style prefabricated wall panels typically reduce build time, reduce labor demand, and reduce waste because large wall sections are installed faster with fewer on-site block-laying steps. Prefabrication is widely cited for shorter construction periods, reduced labor requirements, and reduced material wastage compared to conventional methods. WallPro specifically markets a reduction in construction time “up to 60%,” depending on project conditions.

1) SPEED: fewer steps between “layout” and “wall up”

CHB workflow (why it takes longer)

CHB walls are built in many small units, which creates more steps and waiting time:

deliver blocks + sand + cement

mix mortar constantly

lay blocks course-by-course

cure and correct alignment issues

plastering both sides (often required for finish quality)

more patching (conduits, chases, uneven surfaces)

That’s not “bad”—it’s just step-heavy.

WallPro workflow (why it’s faster)

Panel systems shrink the number of on-site steps because wall sections are installed in larger, repeatable pieces. Prefabrication research consistently notes speed gains because fabrication is standardized and assembly is faster on site.

WallPro’s own materials highlight reducing construction time “up to 60%,” which aligns with the general advantage of panelized systems—especially on projects with clear layouts and repeatable wall lines.

Homeowner effect: Faster “wall-up” stage usually means you hit roofing and weather-tight milestones earlier—reducing the risk of rain delays and long idle periods.

2) LABOR: less manpower tied up for longer periods

CHB is manpower-intensive by nature

CHB relies heavily on masons and helpers for repetitive laying, mortar mixing, alignment checking, and plastering. More steps usually means:

more labor hours

more supervision required

higher risk of small errors turning into rework (plumb/level issues, uneven finishes)

Panel systems reduce labor demand (and rework exposure)

A consistent finding in prefab literature is reduced labor requirements due to quicker installation and more controlled production/assembly.

In plain terms: fewer people are needed for fewer days for the walling stage because you’re not laying hundreds to thousands of individual blocks.

Homeowner effect: Labor-light stages are easier to manage, easier to schedule, and usually produce more predictable progress updates.

3) WASTE: cleaner sites, fewer throwaways, less rework

CHB sites usually generate more waste

CHB work tends to create leftover mortar, broken blocks, off-cuts, packaging, and frequent patching. Waste doesn’t just cost disposal fees—it costs time, handling, and rework cycles.

Prefab/panel systems typically reduce waste

Studies comparing prefabricated vs non-prefabricated projects report lower waste generation with prefabrication; one paper reports prefabricated projects having about 25.85% less total waste generation than non-prefabricated projects (context-dependent). Industry panel suppliers also position “minimal wastage” as a core advantage because panels reduce on-site cutting and wet trades.

Homeowner effect: Cleaner sites tend to move faster (less clutter, fewer delays), and less waste often means fewer surprise “extras” (hauling, disposal, replacement materials).

Simple comparison table (what changes)

Factor | Traditional CHB | WallPro / panelized walls |

Speed | Step-heavy, slower wall-up | Faster wall-up via larger installed sections |

Labor | More labor hours across more days | Reduced labor requirement for walling stage |

Waste | More mortar/breakage/patching | Lower waste generation typical in prefab projects |

The homeowner’s “apples-to-apples” checklist (use this before choosing)

To compare WallPro vs CHB fairly, ask both bidders for:

Wall system scope (exact inclusions, thickness, finish method)

BOQ + exclusions list (so “cheap” doesn’t mean “missing”)

Timeline by milestone (wall-up date, roof date, rough-ins date)

Labor plan (crew size, supervisor presence, projects handled concurrently)

Waste/disposal plan (who pays hauling + dumping, how often cleanup happens)

Rework policy (punchlist handling, defect correction timeline)

If the quote can’t explain those clearly, the system isn’t the problem—the planning is.

Want my copy-paste Wall System Comparison Checklist + BOQ/Exclusions template? Comment PANEL and I’ll send it.

#Cagayandeoroconstruction #cagayandeoroconstructioncompany #wallpropanel #wallpropanelsystems #CagayanDeOro #CDOConstruction #CDOHomeBuilder #WallPro #WallPanels #ConcreteHollowBlocks #BuildFaster #BuildSmart #ConstructionTips #BOQ #CostControl #HomeBuildingPH #DesignAndBuild #SiteVisit #LessRework